What is the Best Binary Trading Platform? Top Recommendations and Reviews

Choosing the Best Binary Trading Platform: Expert Tips and Recommendations Binary trading platforms have become increasingly popular among traders …

Read Article

Understanding and managing inventory movement is a critical aspect of a successful business. Accurately calculating the movement of inventory can help companies make informed decisions, improve efficiency, and optimize profitability.

In this step-by-step guide, we will walk you through the process of calculating movement inventory. We will explore the key components involved, including initial inventory levels, additions, subtractions, and final inventory levels. By following these steps, you will be equipped with the knowledge and skills necessary to effectively calculate movement inventory for your business.

Step 1: Determine Initial Inventory Levels

The first step in calculating movement inventory is to determine the initial inventory levels. This refers to the amount of inventory that a company has at the beginning of a specific period. It can be measured in units, dollars, or any other applicable measurement. To determine the initial inventory levels, you will need to gather data from your records or conduct a physical count of your inventory. It is important to ensure accuracy at this stage, as any discrepancies can significantly impact the accuracy of your calculations.

Step 2: Account for Additions and Subtractions

Once you have determined the initial inventory levels, the next step is to account for additions and subtractions. Additions refer to any new inventory that has been received during the specific period, such as purchases or production. Subtractions, on the other hand, represent any inventory that has been sold, used, or otherwise removed from the inventory during the period. These additions and subtractions should be recorded accurately to reflect the changes in your inventory levels.

Step 3: Calculate Final Inventory Levels

After accounting for additions and subtractions, the final step is to calculate the final inventory levels. This represents the amount of inventory that a company has at the end of the specific period. To calculate the final inventory levels, subtract the subtractions from the initial inventory levels and add the additions. The result will provide you with the final inventory levels, which can be compared to previous periods to track trends and identify potential areas for improvement.

In conclusion, calculating movement inventory is a crucial process for businesses looking to optimize their operations and improve profitability. By following this step-by-step guide, you will be able to accurately determine initial inventory levels, account for additions and subtractions, and calculate final inventory levels. This knowledge will empower you to make informed decisions and drive success in your business.

Read Also: Who did Luongo get traded for - an in-depth look at the trade that shaped Luongo's career

The movement inventory refers to the tracking and calculation of the inventory movements within a company’s supply chain. This involves keeping tabs on the quantities of goods entering and leaving the warehouse, as well as any adjustments made to inventory levels.

By understanding the movement inventory, businesses are able to gain insight into their supply chain operations and make more informed decisions. It allows them to analyze trends, pinpoint areas of inefficiency, and optimize their inventory management processes.

Movement inventory can be categorized into different types, including inbound movements, outbound movements, and internal movements. Inbound movements refer to the receipt of goods from suppliers, while outbound movements involve the shipment of goods to customers. Internal movements refer to the transfer of goods within the company, such as between warehouses or production facilities.

Tracking movement inventory involves various activities, such as recording stock receipts, updating inventory levels, monitoring stock transfers, and tracking customer orders. This information is typically recorded in a centralized inventory management system, which provides real-time visibility into the movement of goods.

By understanding the movement inventory, businesses can effectively manage their stock levels, avoid stockouts, and prevent overstocking. It also enables them to identify any discrepancies or discrepancies in their inventory records, allowing for timely corrections and improvements in accuracy.

In conclusion, understanding movement inventory is crucial for businesses to optimize their supply chain operations and improve inventory management. By accurately tracking and analyzing the movement of goods, businesses can make data-driven decisions and streamline their inventory processes for greater efficiency and profitability.

A movement inventory is a record of the physical movements of goods or products within a supply chain or warehouse. It tracks the movement of items from one location to another, including the quantity, date, and time of each movement. This information is crucial for businesses as it helps them monitor inventory levels, optimize warehouse operations, and improve customer service.

The importance of movement inventory lies in its ability to provide real-time visibility into the movement of goods. By accurately tracking the location and quantity of items, businesses can efficiently manage their inventory and ensure that the right products are available at the right time. This can lead to cost savings by reducing stockouts and overstocks, improving order accuracy, and minimizing the need for expedited shipments.

Read Also: Understanding the Forex Order Book: How It Works and Why It Matters

In addition, movement inventory helps businesses identify bottlenecks or inefficiencies in their supply chain or warehouse operations. By analyzing movement data, companies can identify areas for improvement, such as optimizing storage layouts, streamlining picking and packing processes, or implementing automation technologies.

Furthermore, movement inventory plays a crucial role in providing accurate and timely information to customers. With real-time visibility into the movement of goods, businesses can provide accurate delivery estimates and quickly respond to customer inquiries about the status of their orders. This improves customer satisfaction and loyalty.

In summary, movement inventory is a vital tool for businesses to manage their inventory efficiently, optimize warehouse operations, and provide superior customer service. By tracking the movement of goods and analyzing the data, businesses can make informed decisions, improve operational efficiency, and gain a competitive edge in the market.

Movement inventory refers to the stock of goods that are constantly moving in and out of a company’s inventory. It includes items that are purchased, manufactured, sold, or transferred between locations.

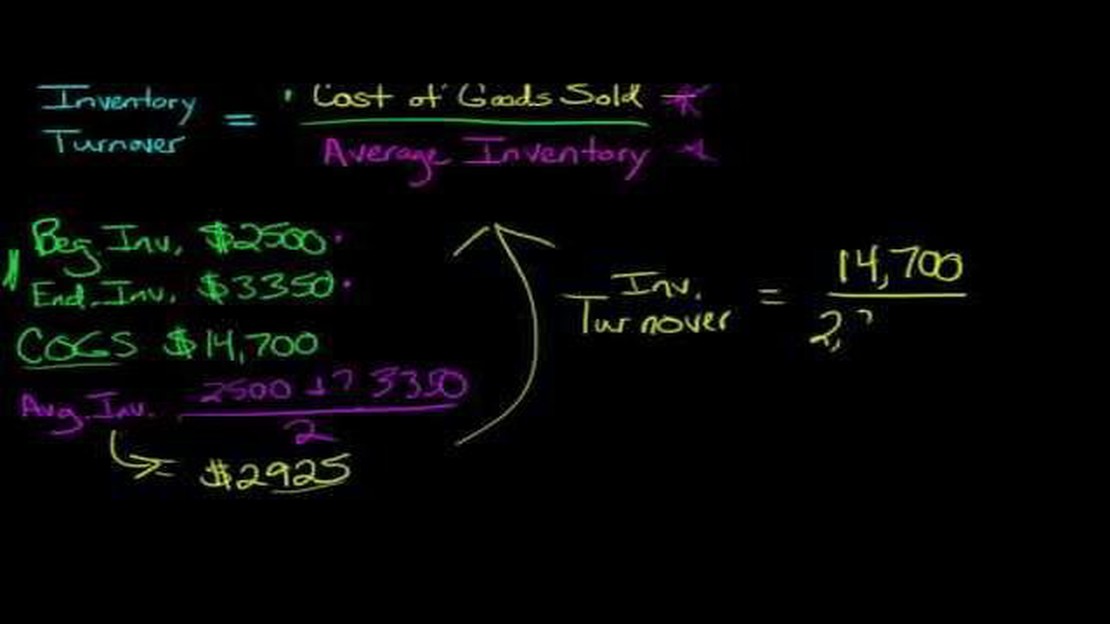

Calculating movement inventory is important for several reasons. Firstly, it helps businesses determine their stock levels and ensure that they have enough inventory to meet customer demands. It also allows companies to identify slow-moving or obsolete items that may be tying up valuable resources. Additionally, knowing the movement inventory enables businesses to optimize their supply chain and plan for future inventory needs.

The first step in calculating movement inventory is to gather the necessary data. This includes information on the beginning inventory, purchases or production during the specified period, sales or transfers out, and the ending inventory. These figures can usually be obtained from the company’s accounting or inventory management system.

To calculate net sales, you need to subtract any sales returns or allowances from the gross sales. This will give you the actual amount of sales revenue earned by the company during the specified period.

There are several common inventory valuation methods, including First-In, First-Out (FIFO), Last-In, First-Out (LIFO), and Weighted Average Cost. FIFO assumes that the oldest items are sold first, while LIFO assumes that the newest items are sold first. The weighted average cost method calculates the average cost of all items in inventory and assigns that cost to each unit sold.

Choosing the Best Binary Trading Platform: Expert Tips and Recommendations Binary trading platforms have become increasingly popular among traders …

Read ArticleIs Czech koruna still valid? The Czech koruna is the official currency of the Czech Republic. It has been in circulation since 1993, when the …

Read ArticleIs OANDA legal in Malaysia? If you are a resident of Malaysia and interested in trading in the foreign exchange market, you may have heard of OANDA. …

Read ArticleIs Primerica a good stock to buy? When considering whether Primerica stock is a good investment, it is important to analyze the company’s financial …

Read ArticleCost of Autopilot Trading App: A Complete Breakdown The emergence of autopilot trading apps has revolutionized the way people invest in financial …

Read ArticleIs QQQ an exchange-traded fund? If you are new to investing, you may have heard the term “Exchange-Traded Fund” (ETF) thrown around. ETFs have gained …

Read Article