What is MCX in India? Understanding the Multi Commodity Exchange of India

Exploring the MCX Market in India: Everything You Need to Know The Multi Commodity Exchange of India, also known as MCX, is the premier commodity …

Read Article

Moving average is a commonly used statistical tool in production management that helps businesses analyze and forecast their production processes. It provides valuable insights into the performance of a production system, enabling managers to make informed decisions and optimize their operations.

In simple terms, a moving average is a calculation of the average value of a series of data points over a certain period of time. It is widely used in production management because it helps smooth out the fluctuations and noise in production data, making it easier to identify trends and patterns.

By calculating the moving average, production managers can better understand the overall production performance and make more accurate predictions about future production levels. This is especially important in industries where demand for products fluctuates regularly.

For example, in the automotive industry, the moving average can help production managers anticipate periods of high demand and adjust their production schedules accordingly. By analyzing the moving average over a period of time, managers can identify seasonal patterns or trends and plan their production accordingly.

Furthermore, the moving average can also be used to evaluate the effectiveness of production improvement initiatives. By comparing the moving average before and after implementing changes, managers can determine whether the changes have had a positive impact on production performance or not.

In conclusion, understanding the role of moving average in production management is crucial for businesses looking to optimize their production processes and improve their overall performance. By analyzing and forecasting production data using moving averages, managers can make informed decisions, identify trends, and plan for future demand, ultimately leading to increased efficiency and profitability.

The moving average is a statistical calculation used in production management to analyze and forecast the future trend of a set of data points. It is a commonly used technique in various industries, such as manufacturing, finance, and inventory management.

The moving average is calculated by taking the average of a specific number of data points within a given time period. The number of data points and the length of the time period can vary depending on the specific application and the desired level of accuracy.

The purpose of using a moving average is to smoothen the data and remove any short-term fluctuations or noise that may be present. This helps in identifying the underlying trend or pattern in the data, making it easier to make predictions or decisions based on the historical data.

There are different types of moving averages that can be used, such as the simple moving average (SMA) and the exponential moving average (EMA). The simple moving average gives equal weightage to all the data points within the time period, while the exponential moving average gives more weightage to the recent data points.

The moving average is often displayed as a line graph or a chart, with the time period on the x-axis and the average value on the y-axis. This visual representation makes it easier to interpret and analyze the data.

Read Also: Is a diamond pattern bearish? The technical analysis of diamond chart patterns

In production management, the moving average can be used to forecast the demand for products, plan production schedules, adjust inventory levels, and optimize resource allocation. By analyzing the historical data and identifying the trend, managers can make informed decisions to improve efficiency, minimize costs, and avoid the risk of overproduction or stockouts.

In conclusion, the moving average is a powerful tool in production management that helps in analyzing and forecasting the future trend of a set of data points. By smoothening the data and removing short-term fluctuations, it provides valuable insights for decision-making and optimization in various industries.

Moving Average is a vital tool in production management that helps businesses analyze and forecast their production patterns. It is a statistical calculation that provides insights into the trends and fluctuations in the production process.

The moving average is calculated by taking the average of a set of data points over a specific time period. It smoothes out the irregularities and noise in the data, making it easier to identify the underlying trends. This allows production managers to make informed decisions and adjustments to optimize their production processes.

One of the key benefits of using moving averages in production management is its ability to detect seasonality. Seasonal patterns can have a significant impact on production, such as increased demand during specific months or decreased sales during certain periods. By analyzing the moving averages, production managers can identify these seasonal patterns and adjust their production plans accordingly to maximize efficiency and minimize costs.

Another advantage is that the moving average helps in predicting future production levels. By analyzing the historical data and calculating the moving average, production managers can forecast the expected production levels in the coming periods. This enables them to anticipate fluctuations in demand and adjust their resources, such as labor and raw materials, accordingly to avoid any shortages or overages.

Read Also: Understanding Box 14 on W-2: Explanation and Codes

In addition, moving averages provide a benchmark for performance evaluation. By comparing the actual production levels with the moving average, production managers can assess the effectiveness of their production strategies and identify any areas for improvement. This allows them to fine-tune their processes and make data-driven decisions to enhance overall productivity.

Overall, the moving average plays a crucial role in production management by providing valuable insights into production patterns, detecting seasonality, predicting future production levels, and facilitating performance evaluation. By leveraging this statistical calculation, businesses can optimize their production processes, improve efficiency, and meet customer demand effectively.

The moving average in production management is a calculation used to analyze data over a certain time period and smooth out any random fluctuations or irregularities in the data. It is commonly used to forecast future demand, track inventory levels, and determine the optimal level of production.

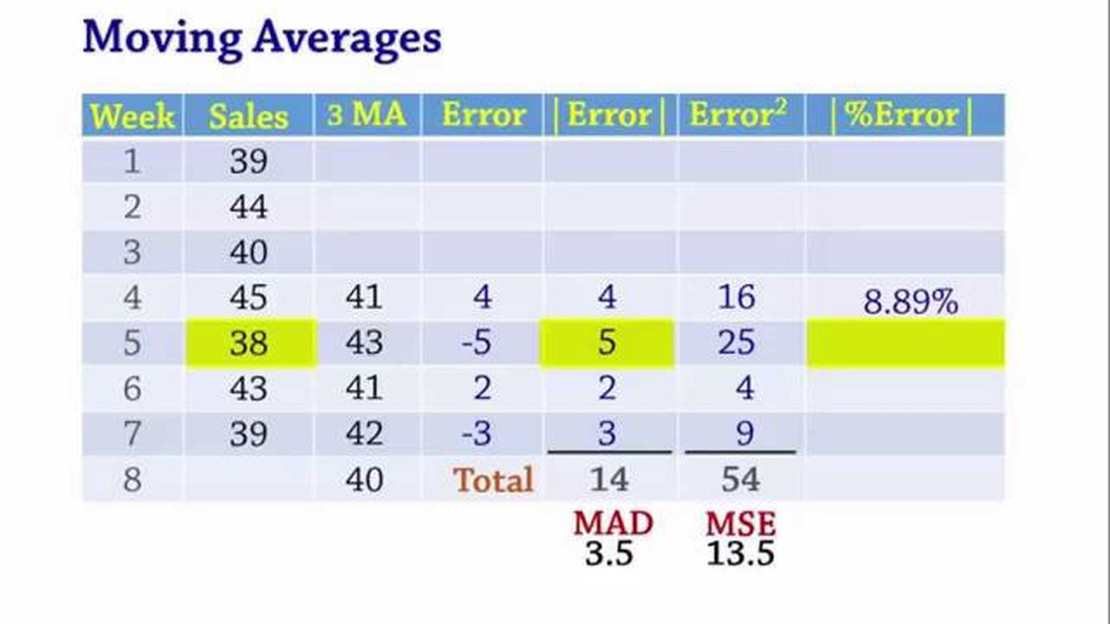

The moving average is calculated by taking the average of a set of data points over a specific time period. For example, if you are using a 3-month moving average, you would take the average of the production data from the past three months. This average is then used to forecast future demand or track inventory levels.

The moving average is important in production management as it helps in forecasting future demand, tracking inventory levels, and making informed decisions about the optimal level of production. By smoothing out any random fluctuations in the data, the moving average provides a more accurate representation of the underlying trend and helps in making more accurate predictions.

Yes, the moving average can be used for short-term forecasting in production management. By calculating the moving average over a shorter time period, such as a week or a month, you can track recent trends and make predictions about future demand or production levels in the near future. However, it is important to note that the moving average is more commonly used for longer-term forecasting.

Yes, there are some limitations and drawbacks to using the moving average in production management. One limitation is that it assumes a constant underlying trend in the data, which may not always be the case. It also tends to lag behind sudden changes or shifts in the data, as it is based on historical averages. Additionally, the moving average may not be suitable for data with extreme fluctuations or seasonality patterns.

Moving averages are used in production management to analyze and predict trends in production data. By calculating the average value of a set of data points over a specific time period, moving averages can help identify patterns and fluctuations in production output. This information can then be used to make informed decisions about production planning, resource allocation, and inventory management.

Moving averages can be used to optimize production processes by providing insights into production trends and forecasting future production levels. By calculating and analyzing moving averages, production managers can identify potential bottlenecks or inefficiencies in the production process and take appropriate actions to improve productivity. For example, if the moving average indicates a decline in production output, managers can investigate the cause and make adjustments to the production line or allocate additional resources to maintain optimal production levels.

Exploring the MCX Market in India: Everything You Need to Know The Multi Commodity Exchange of India, also known as MCX, is the premier commodity …

Read ArticleRegulated swaps by the CFTC: An overview The Commodity Futures Trading Commission (CFTC) is the regulatory body responsible for overseeing and …

Read ArticleUnderstanding the Average Speed of a Time Interval Have you ever wondered how to calculate the average speed of an object over a given time interval? …

Read ArticleRegulation of Forex Trading in South Africa Forex trading is a popular investment option for individuals in South Africa, as it offers the potential …

Read ArticleUnderstanding the Volume Price in Forex Trading When it comes to trading in the foreign exchange market (Forex), understanding volume price is crucial …

Read ArticleUnderstanding How Futures Work Interested in the world of finance? Futures trading is a critical component of the global financial markets, allowing …

Read Article