Step-by-Step Guide: Downloading and Installing WiFi Drivers for Windows 10

Download and Install WiFi Drivers for Windows 10 Is your WiFi connection on your Windows 10 computer not working properly? One possible solution to …

Read Article

The APQR (Automated Process Quality Reporting) system is widely used in industries to monitor and evaluate the quality of production processes. Two key statistical measures used in APQR are the UCL (Upper Control Limit) and LCL (Lower Control Limit). These limits are crucial in determining whether a process is within acceptable limits or if it requires adjustments to maintain quality standards.

The UCL represents the upper boundary or threshold of acceptable variation in a process. It is calculated based on statistical methods and represents the maximum limit of acceptable variation. When a process exceeds this limit, it indicates that there is a significant deviation from the expected values, and corrective actions are required to bring the process back into control.

On the other hand, the LCL is the lower boundary or threshold of acceptable variation. It is also calculated based on statistical methods and represents the minimum limit of acceptable variation. When a process falls below this limit, it indicates that there is a significant deviation from the expected values in the opposite direction. In such cases, corrective actions are required to bring the process back into control and maintain quality standards.

By monitoring a process using UCL and LCL values, organizations can effectively identify and address variations in production processes and ensure consistent quality output. This comprehensive guide will delve into the intricacies of UCL and LCL, their calculation methods, and how to interpret and leverage these measures to optimize process control and enhance overall product quality.

Throughout this guide, we will provide detailed explanations, examples, and practical tips to help you fully grasp the concept of UCL and LCL and gain a solid understanding of their significance in APQR. Whether you are new to the field of quality assurance or a seasoned professional, this guide will serve as a valuable resource to enhance your knowledge and skills in process control.

UCL and LCL stand for Upper Control Limit and Lower Control Limit respectively. These terms are commonly used in the field of statistical process control (SPC) to determine the bounds within which a process is considered to be under control. UCL and LCL are integral components of the control chart, which is a graphical tool used to monitor the stability and performance of a process over time.

The control chart consists of a central line, usually the process mean, and two control limits - the UCL and LCL. The UCL represents the upper boundary, while the LCL represents the lower boundary, of acceptable process variation. Any data point plotted outside these control limits implies that the process is out of control and requires attention and investigation.

Read Also: Understanding Currency Options Trading: Step-by-Step Guide

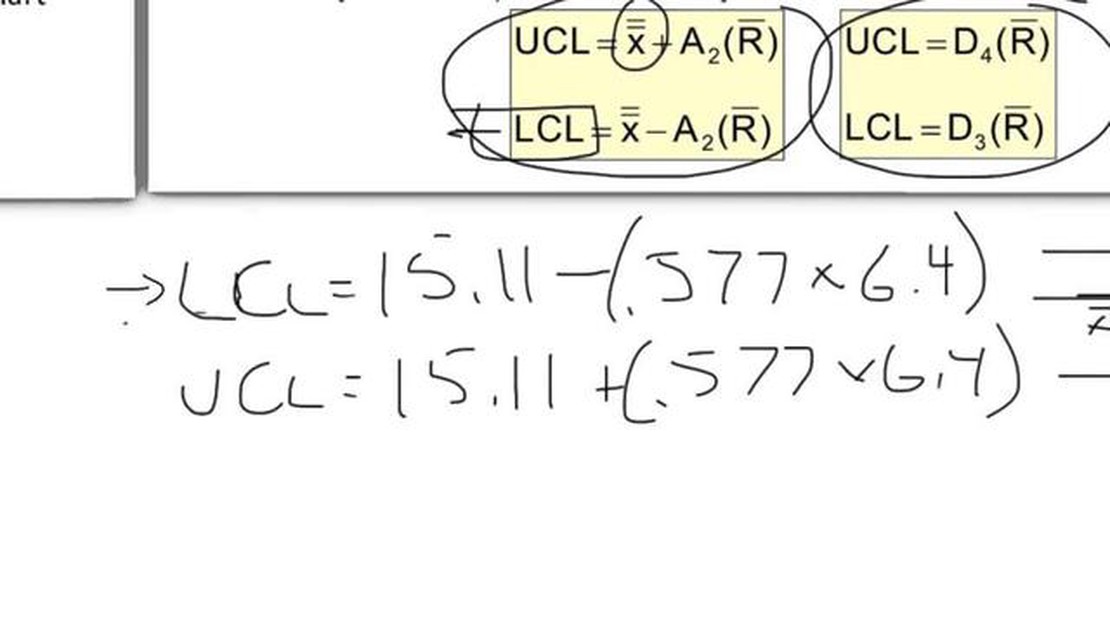

The calculation of UCL and LCL is typically based on statistical principles and depends on various factors, including the data distribution, sample size, and desired level of control. Common methods used to determine these values include the classical method, based on the standard deviation, and the Western Electric rules, which account for the presence of special cause variation.

In addition to their use in process control, UCL and LCL also play a crucial role in the analysis of process capability. By comparing the process mean and variation against these control limits, practitioners can assess whether a process is capable of meeting the required specifications. If the process mean or variation falls outside the control limits, process improvement efforts may be necessary to bring the process back within acceptable limits.

Overall, UCL and LCL are essential tools for monitoring and managing process performance. They provide organizations with a systematic method for identifying and addressing process variability, helping to ensure consistent quality and efficiency in their operations.

UCL (Upper Control Limit) and LCL (Lower Control Limit) play a vital role in the process of Advance Product Quality Reporting (APQR). These statistical control limits define the range within which the process is expected to operate, providing a benchmark against which to measure the performance of a system.

UCL represents the highest value at which the process is considered to be under control, while LCL represents the lowest value at which the process is considered to be under control. These limits are determined based on historical data, variance, and desired levels of quality. By comparing actual data with these control limits, organizations can quickly identify when a process is deviating from the norm and take corrective action.

UCL and LCL act as decision thresholds, allowing organizations to distinguish between normal process variation and special causes of variation, enabling them to detect and address any issues that may affect product quality. Additionally, they help organizations identify trends and patterns, leading to process improvement.

In APQR, UCL and LCL are used in conjunction with statistical process control (SPC) methods to monitor, analyze, and control the performance of processes. By continuously monitoring data and comparing it to these control limits, organizations can identify any variations that may indicate a problem and implement corrective actions in a timely manner.

Overall, UCL and LCL are crucial in APQR as they provide a standardized framework for assessing and maintaining process stability, enabling organizations to ensure consistent and high-quality products. By using these control limits effectively, organizations can improve efficiency, reduce defects, and enhance customer satisfaction.

Read Also: Understanding Forex Price Action: How it Impacts Trading and Profitability

APQR stands for Attribute Precision Quality Ratio.

UCL, or Upper Control Limit, is important in APQR as it helps determine the upper bound beyond which an attribute’s precision is considered unacceptable.

UCL is calculated in APQR by adding three standard deviations to the average precision of the attribute being measured.

LCL stands for Lower Control Limit, and it is used to determine the lower bound below which an attribute’s precision is considered unacceptable.

Yes, the UCL and LCL values can be modified in APQR based on specific requirements or industry standards.

APQR stands for Attribute Performance Quality Rating. It is a method used to assess the quality and performance of attributes in a product. It involves assigning a rating to each attribute based on its importance and performance.

Download and Install WiFi Drivers for Windows 10 Is your WiFi connection on your Windows 10 computer not working properly? One possible solution to …

Read ArticleTypes of Options in Trading: A Comprehensive Guide Options trading can be an exciting and lucrative venture for investors looking to diversify their …

Read ArticleWhat is time trading system? In today’s fast-paced world, time is a valuable resource. We are constantly looking for ways to optimize our time …

Read ArticleWhat is the Highest Euro to Dollar History? The Euro to Dollar exchange rate has reached historic heights, with the Euro now trading at its highest …

Read ArticleIs KOSDAQ open today? Are you interested in trading on the KOSDAQ? It’s important to know the trading hours and schedule to plan your investments …

Read ArticleCalculating Compensation Cost: A Comprehensive Guide In today’s competitive job market, it is crucial for businesses to attract and retain top talent. …

Read Article