Is MQL5 MetaTrader 5? Unveiling the Similarities and Differences

Is MQL5 MetaTrader 5? When it comes to trading in the financial markets, having access to the right tools and platforms is crucial. Two popular …

Read Article

The moving average is a statistical technique widely used in supply chain management to analyze and predict trends in data. It is particularly useful for smoothing out fluctuations in demand or inventory levels, allowing companies to make more accurate forecasts and better allocate resources.

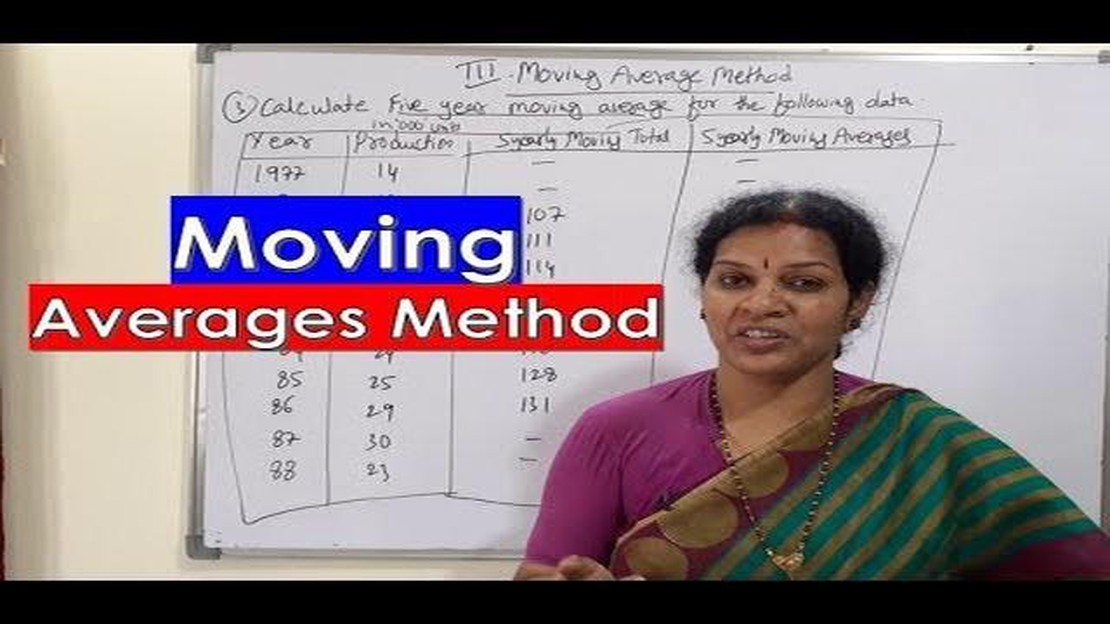

A moving average calculates the average value of a set of data points over a specific period, such as months or quarters. It is called a “moving” average because it calculates the average continuously as new data becomes available, dropping the oldest data point and adding the newest one. This helps to identify and understand trends by reducing the impact of random or temporary fluctuations.

In supply chain management, the moving average is often used to forecast demand or inventory levels. By analyzing historical data, companies can calculate the moving average and determine the average demand or inventory level over a specific period. This information can then be used to make predictions about future demand and plan production, ordering, and inventory management accordingly.

The moving average can also be used to identify seasonality or cycles in demand. By plotting the moving average on a graph, companies can visualize patterns and fluctuations over time. This can help them identify recurring trends and adjust their supply chain strategies to better align with customer demand and preferences.

In supply chain management, the moving average is a statistical calculation used to analyze and forecast data trends. It is a commonly used method to measure and understand the average value of a data set across different periods of time.

The moving average is calculated by taking the sum of a set of data points over a specified time period and dividing it by the number of data points in that period. This calculation is then repeated for each subsequent period, creating a moving average that changes as new data is added.

The moving average is particularly useful in supply chain management because it helps to smooth out fluctuations and identify patterns in data. By analyzing the moving average, supply chain managers can gain insights into demand patterns, detect seasonality, and identify potential trends or discrepancies in their operations.

For example, a supply chain manager may use the moving average to analyze their sales data over the past six months. By calculating and analyzing the moving average, they can identify any upward or downward trends in sales and adjust their inventory levels or production forecasts accordingly.

Furthermore, the moving average can be used in conjunction with other forecasting techniques, such as exponential smoothing or regression analysis, to improve the accuracy of supply chain forecasts. By incorporating the moving average into their forecasting models, supply chain managers can make more informed decisions and optimize their operations.

Key benefits of using moving average in supply chain management:

In summary, the moving average is an essential tool in supply chain management that helps to analyze and forecast data trends. By calculating and analyzing the moving average, supply chain managers can gain valuable insights into their operations and make data-driven decisions to optimize their supply chain performance.

There are several types of moving averages that can be used in supply chain management:

1. Simple Moving Average (SMA): This is the most basic type of moving average, where the average is calculated by summing up a set of data points and dividing it by the number of data points. SMA gives equal weightage to all the data points in the period.

Read Also: How to Calculate the Moneyness of an Option: A Step-by-Step Guide

2. Weighted Moving Average (WMA): WMA assigns different weights to the data points based on their importance. The weights can be predefined or dynamically adjusted based on business needs. This type of moving average can give more emphasis to recent data points.

3. Exponential Moving Average (EMA): EMA gives more weight to recent data points and less weight to older data points. It uses an exponential smoothing factor to determine the weights. EMA is more responsive to recent changes in the data and can provide a better indication of the current trend.

4. Cumulative Moving Average (CMA): CMA is calculated by taking the average of all the data points up to a specific point in time. It gives equal weightage to all the data points that have been observed until that point.

5. Adaptive Moving Average (AMA): AMA adjusts the period of the moving average based on the volatility of the data. It can automatically lengthen or shorten the time period based on the market conditions. AMA is useful in supply chain management as it can adapt to changing demand patterns and identify trends more accurately.

Each type of moving average has its own advantages and disadvantages, and the choice of which one to use depends on the specific requirements of the supply chain management process and the characteristics of the data being analyzed.

In supply chain management, the moving average is a crucial tool that helps businesses make informed decisions and plan for the future. It is a statistical concept that calculates the average value of a series of data points over a specific period of time and is used to analyze trends and patterns.

Read Also: What is an Example of a PI System? Our Top Picks

The moving average can be used to forecast demand, track inventory levels, and optimize production schedules. By analyzing historical data, businesses can identify seasonal fluctuations, identify trends, and make accurate predictions for future demand.

One of the key advantages of using the moving average in supply chain management is its ability to smooth out fluctuations and provide a more accurate representation of the overall trend. This helps businesses to avoid overstocking or understocking inventory, leading to cost savings and improved customer satisfaction.

The moving average also allows businesses to identify and respond quickly to changes in demand. By regularly updating the moving average calculation, businesses can adjust their production plans and inventory levels based on the latest demand trends. This helps to minimize stockouts and reduce lead times, improving overall customer service.

Furthermore, the moving average can also be used to analyze supplier performance and monitor overall supply chain efficiency. By calculating the moving average of lead times, businesses can identify any delays or inefficiencies in their supply chain and take proactive measures to address them. This can lead to improved delivery times, reduced costs, and better supplier relationships.

| Benefits of Moving Average in Supply Chain Management |

|---|

| 1. Accurate demand forecasting |

| 2. Optimal inventory management |

| 3. Improved production planning |

| 4. Quick response to changes in demand |

| 5. Enhanced supply chain performance |

| 6. Cost savings and improved customer satisfaction |

In conclusion, the moving average plays a significant role in supply chain management. By providing businesses with accurate demand forecasts, optimal inventory management, and improved production planning, it helps them to make informed decisions and stay competitive in today’s dynamic market. It is an essential tool for any business looking to optimize their supply chain operations and improve customer service.

A moving average is a statistical technique used to analyze data over a defined period of time. In supply chain management, it can be used to track and predict trends in demand, identify potential supply chain disruptions, and optimize inventory levels.

A moving average helps in forecasting demand by smoothing out the fluctuations in data over a specific time period. It considers historical data points and calculates the average value, which can provide a more accurate estimate of future demand.

The advantages of using a moving average in supply chain management include improved demand forecasting accuracy, better visibility into demand trends, the ability to identify and react to supply chain disruptions, and optimized inventory management.

Yes, a moving average can be used for inventory optimization. By analyzing the moving average of demand, companies can determine the appropriate inventory levels to meet customer demand while minimizing excess and obsolete inventory.

The limitations of using a moving average in supply chain management include the assumption of a constant trend, the inability to account for sudden changes or disruptions in demand, and the reliance on historical data, which may not always reflect future patterns accurately.

Is MQL5 MetaTrader 5? When it comes to trading in the financial markets, having access to the right tools and platforms is crucial. Two popular …

Read ArticleBest Places to Exchange Dollars in Thailand Thailand is a popular tourist destination known for its beautiful beaches, rich cultural heritage, and …

Read ArticleUnderstanding Leading Indicators in Day Trading Day trading is a fast-paced, high-risk endeavor that requires precision and knowledge of market …

Read ArticleBest Range for RSI: Finding the Ideal Value The Relative Strength Index (RSI) is a popular technical indicator used in stock trading and other …

Read ArticleIs IBKR good for options? When it comes to options trading, the choice of broker can make a significant impact on your overall trading experience. One …

Read ArticleUnderstanding the Difference Between FFT and IDFT The Fast Fourier Transform (FFT) and the Inverse Discrete Fourier Transform (IDFT) are two …

Read Article