Is Fair Market Value the Same as Share Price? Understanding the Difference

Understanding the Difference Between Fair Market Value and Share Price When it comes to investing in stocks, understanding the difference between fair …

Read Article

Quality control is a critical aspect of any manufacturing process, ensuring that products meet the desired standards and specifications. One commonly used method in quality control is the moving average method. This method allows for the analysis of data over a specific time period, providing valuable insights into the performance and stability of a process.

The moving average method involves calculating the average of a set of data points within a defined time frame. By doing so, it smooths out the fluctuations in the data and highlights any underlying trends or patterns. This makes it easier to identify variations and anomalies that may indicate a problem with the process.

Using the moving average method in quality control requires careful consideration of several key factors. Firstly, the length of the time frame chosen can significantly impact the accuracy and sensitivity of the analysis. Shorter time frames may capture more immediate changes, while longer time frames can provide a broader picture of overall performance.

It is also important to take into account the type of moving average used. Simple moving averages treat all data points equally, while weighted moving averages assign different weights to each data point based on their relevance. Exponential moving averages, on the other hand, give more weight to recent data points.

By understanding the moving average method and its various components, quality control professionals can effectively monitor and improve processes, ensuring consistent and high-quality outputs. This comprehensive guide aims to elucidate the intricacies of the moving average method and its practical applications in quality control.

The Moving Average Method is a widely used statistical technique in quality control that is used to analyze time series data. It is a simple and effective method for identifying trends and patterns in data over a specific time period.

The Moving Average Method calculates the average value of a set of data points over a determined number of periods. This average is then used to smooth out the fluctuations in the data and highlight the underlying trends. By analyzing the trends, organizations can better understand the performance of a process or system and make informed decisions to improve quality control.

The Moving Average Method is particularly useful in quality control because it provides a level of smoothness to the data, making it easier to identify changes in the process over time. It helps in identifying any sustained increase or decrease in the mean value, which can indicate a shift in the process that may require corrective action.

There are different variations of the Moving Average Method, such as the Simple Moving Average (SMA) and the Weighted Moving Average (WMA). The SMA gives equal importance to all data points, while the WMA assigns different weights to each data point based on its relative importance. The choice of the moving average type depends on the specific requirements of the quality control analysis and the characteristics of the data.

To implement the Moving Average Method, organizations need to collect and organize the time series data into a table. They then determine the number of periods to include in the moving average calculation and apply the appropriate formula. The moving average values can be plotted on a chart to visualize the trends and patterns over time.

Read Also: Discover the TWS Strategy Lab: Unveiling the Secrets of Effective Trading Strategies

In conclusion, the Moving Average Method is a valuable tool in quality control that helps organizations analyze time series data, identify trends, and make informed decisions to improve processes and systems. By understanding the underlying trends, organizations can proactively address issues and maintain high levels of quality in their products or services.

The moving average method is a widely used technique in quality control that offers several important benefits:

1. Smoothing Out Variations: By taking the average of several data points, the moving average method helps to smooth out the variations in the data. This can be particularly useful when dealing with noisy or erratic data, as it provides a more stable representation of the underlying trend or pattern.

2. Identifying Trends: The moving average method is an effective tool for identifying trends in the data. By calculating the average over a specific time period, it allows you to detect whether the data is moving upwards, downwards, or staying relatively constant. This information can be invaluable in making informed decisions or predictions.

3. Forecasting Future Values: Another significant benefit of the moving average method is its ability to forecast future values. By extending the moving average into the future, it is possible to estimate what the future data points might look like based on the historical data. This can be incredibly helpful in areas such as sales forecasting or demand planning.

4. Signal Detection: The moving average method can also be used to detect signals or anomalies in the data. By comparing the actual data points to the moving average, it becomes easier to identify any unexpected or significant deviations. This can be a valuable tool for detecting potential quality issues or process changes.

Read Also: Understanding the Basics of VGA TV Connection: All You Need to Know

5. Easy to Understand and Implement: One of the greatest advantages of the moving average method is its simplicity. The concept is easy to understand, and the calculations are straightforward to implement. This makes it accessible to a wide range of users, regardless of their level of expertise in statistics or quality control.

In conclusion, the moving average method offers numerous benefits in quality control, including smoothing out variations, identifying trends, forecasting future values, signal detection, and ease of implementation. By leveraging this technique, organizations can gain valuable insights into their data and make informed decisions to improve their processes and outcomes.

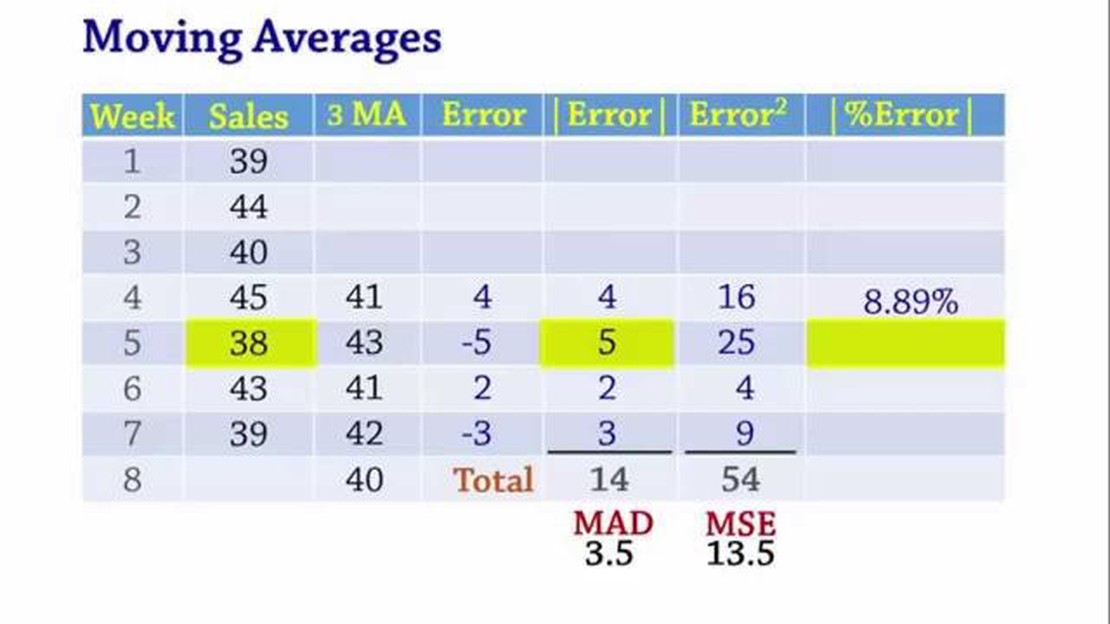

The moving average method in quality control is a statistical technique used to analyze data over time. It involves calculating the average of a specified number of consecutive data points at different time intervals.

The moving average is calculated by adding up a certain number of consecutive data points and dividing the sum by the number of data points. The process is repeated for each subsequent interval, creating a series of average values over time.

The moving average method is used in quality control because it helps to identify trends and patterns in data over time. By smoothing out random fluctuations, it allows for a better understanding of the underlying process and helps to predict future outcomes.

There are several advantages of using the moving average method in quality control. It helps to detect shifts or changes in the data that may signify a problem in the production process. It is also useful for forecasting future data points and identifying long-term trends.

One limitation of the moving average method is that it can be influenced by outliers or extreme data points. It may also lag behind sudden changes in the data, as it is based on a rolling average. Additionally, it may not be suitable for data with seasonal or cyclical patterns.

The moving average method in quality control is a statistical technique used to analyze and monitor processes by calculating the average of a set of data points over a specific period of time.

The moving average method is used in quality control to detect trends and patterns in process data. It helps to identify variations and deviations from the mean, allowing quality control professionals to take corrective actions to improve the process.

Understanding the Difference Between Fair Market Value and Share Price When it comes to investing in stocks, understanding the difference between fair …

Read ArticleIs covered call always profitable? A covered call strategy is a popular option trading technique that involves selling call options on an underlying …

Read ArticleSGX Trading: A Step-by-Step Guide Welcome to our beginner’s guide on how to trade on the Singapore Exchange (SGX). Whether you’re new to trading or …

Read ArticleMembers of PMEX: A Comprehensive Overview PMEX, or the Pakistan Mercantile Exchange, is a leading commodities exchange in Pakistan. It provides a …

Read ArticleUnderstanding the Foreign Exchange Market in Nigeria Nigeria, often referred to as the “Giant of Africa”, is not only the largest economy on the …

Read ArticleWhat are the issues with stock options in a compensation plan? Stock options have long been a popular component of compensation plans for employees, …

Read Article